The History of the Hensley Bulk Feed Trailer

The year is 1962, and many things are going on in the world. The Cuban Missile Crisis begins, Eleanor Roosevelt passes away, and Wal-Mart and K-Mart, two of the largest retailers in the world open their doors for the first time. But in Tippecanoe, Indiana, another company would get its start from an accident and a dream, and a new Family Legacy was born with a 28-year-old man named Paul Hensley.

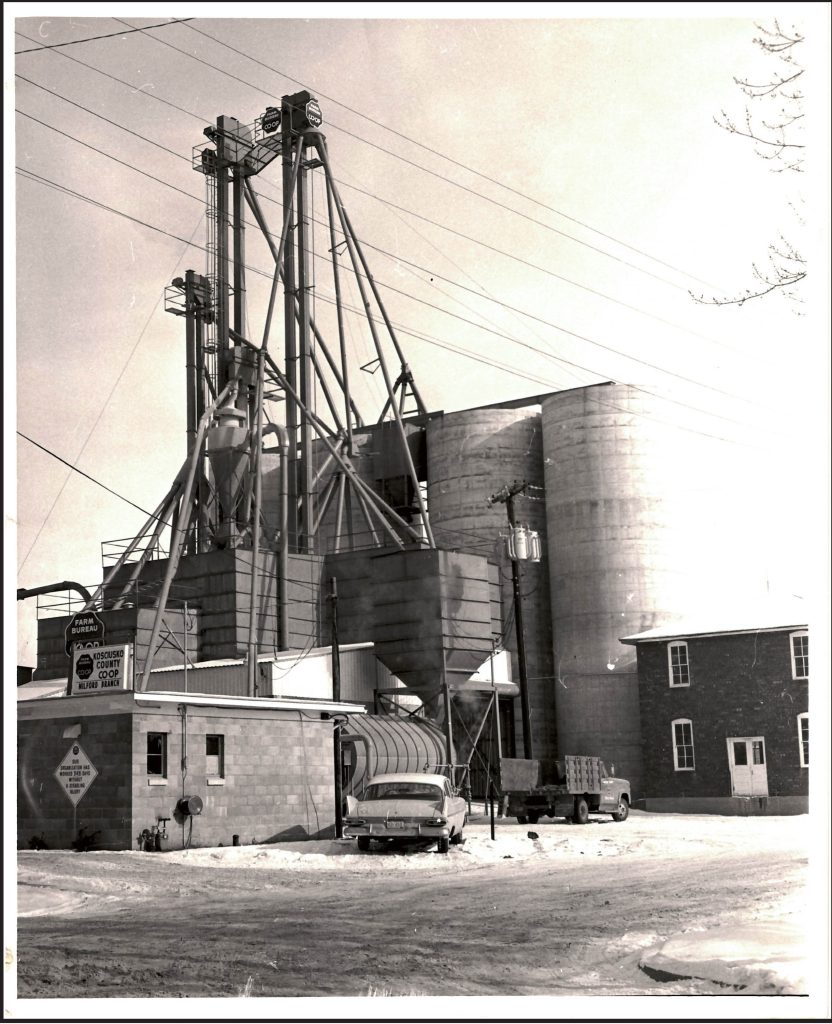

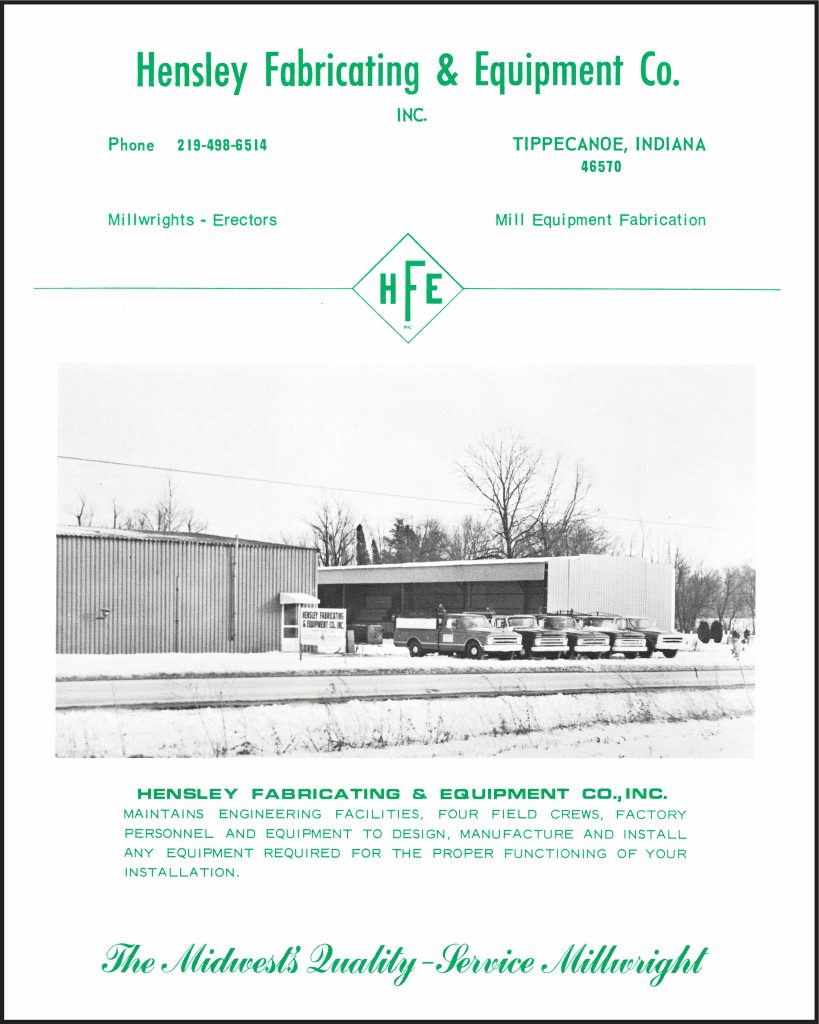

Hensley Fabricating & Equipment Co. opened their doors for business in spring of 1962. They started out with humble beginnings with their two founders, Paul and Joyce Hensley, still currently of Tippecanoe and still involved in day-to-day operations. Paul had been working with a millwright company out of Burket, IN up until 1961 when the company had to close their doors in bankruptcy. He then found employment at I & M Manufacturing of Bourbon, where he worked for a couple months, when he got hurt on the job airing up an old, split-rim semi tire. After surgery and a couple days in the hospital, Paul decided to go into business for himself; not building bulk feed trucks, but doing millwright work. Paul and Joyce went to the local bank and borrowed their first business loan; $700 to purchase a used Chevy Pickup, which was used as their first service truck, and they worked for the first two years out of Paul’s father-in-laws barn, formerly Ed Halls Blacksmith Shop.

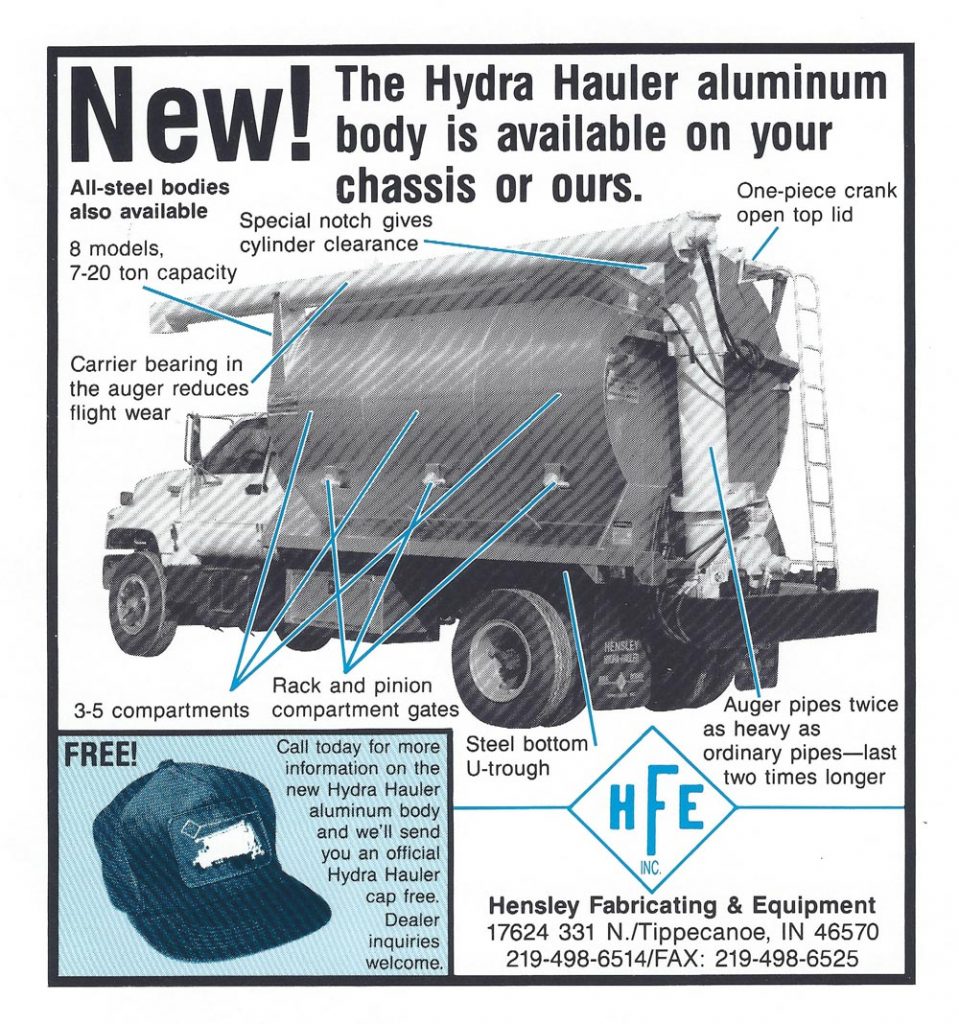

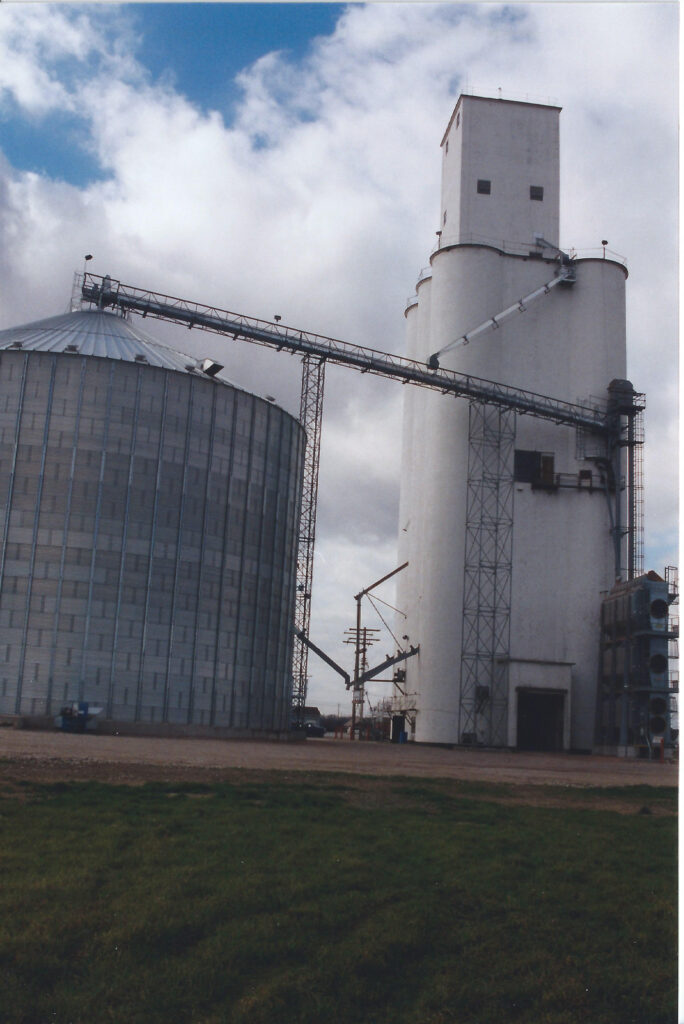

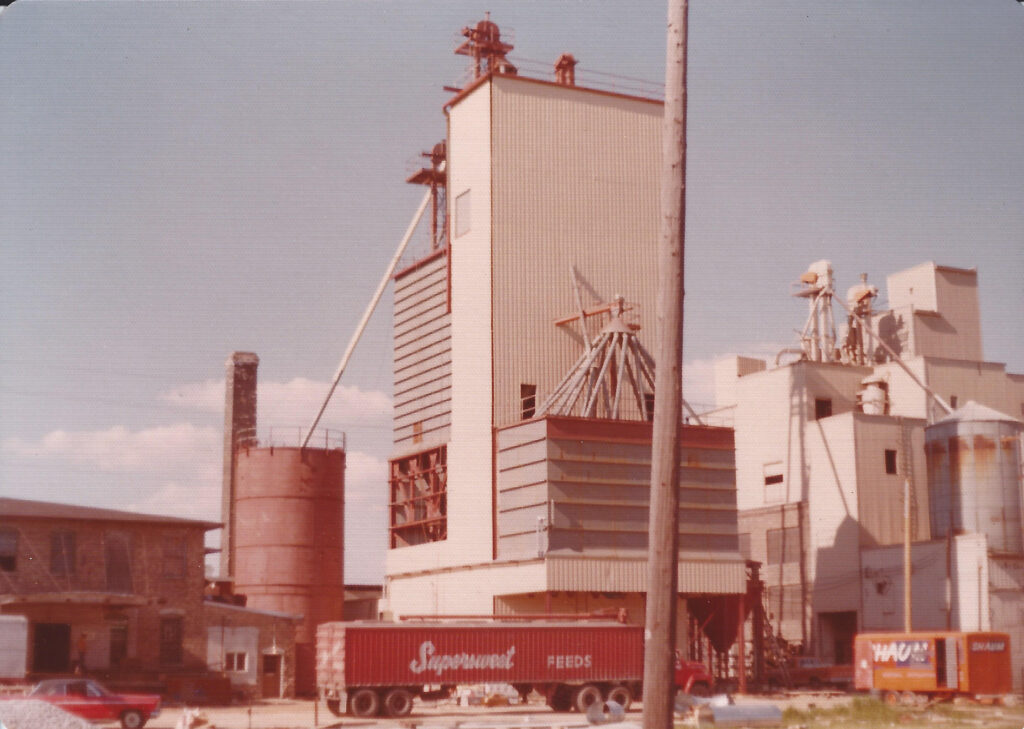

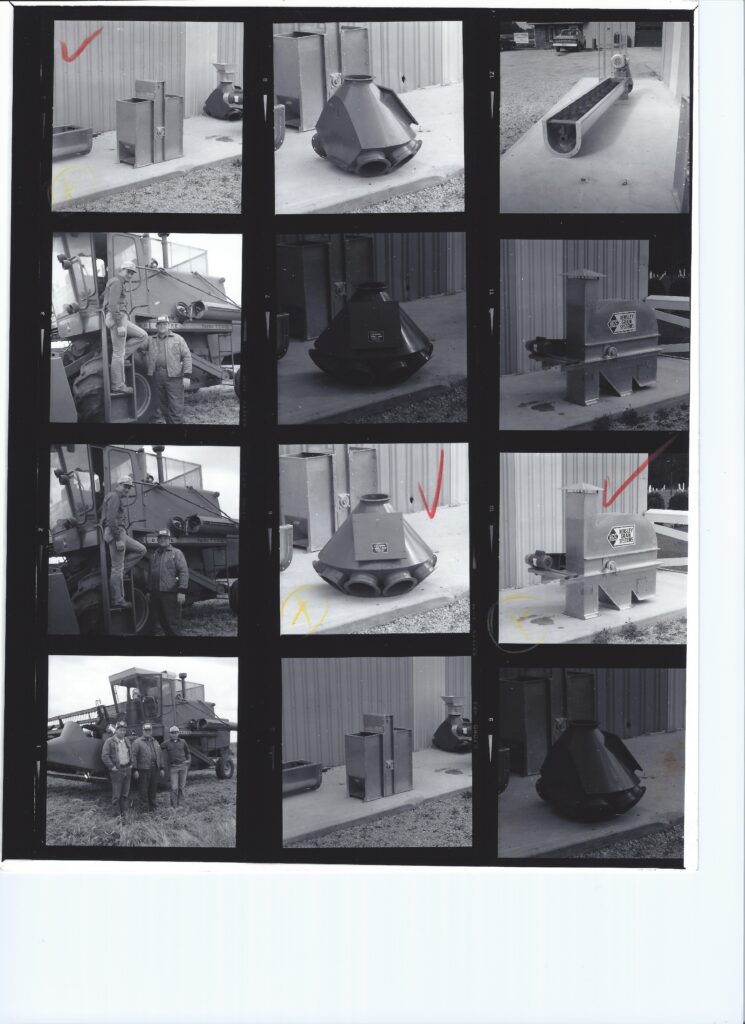

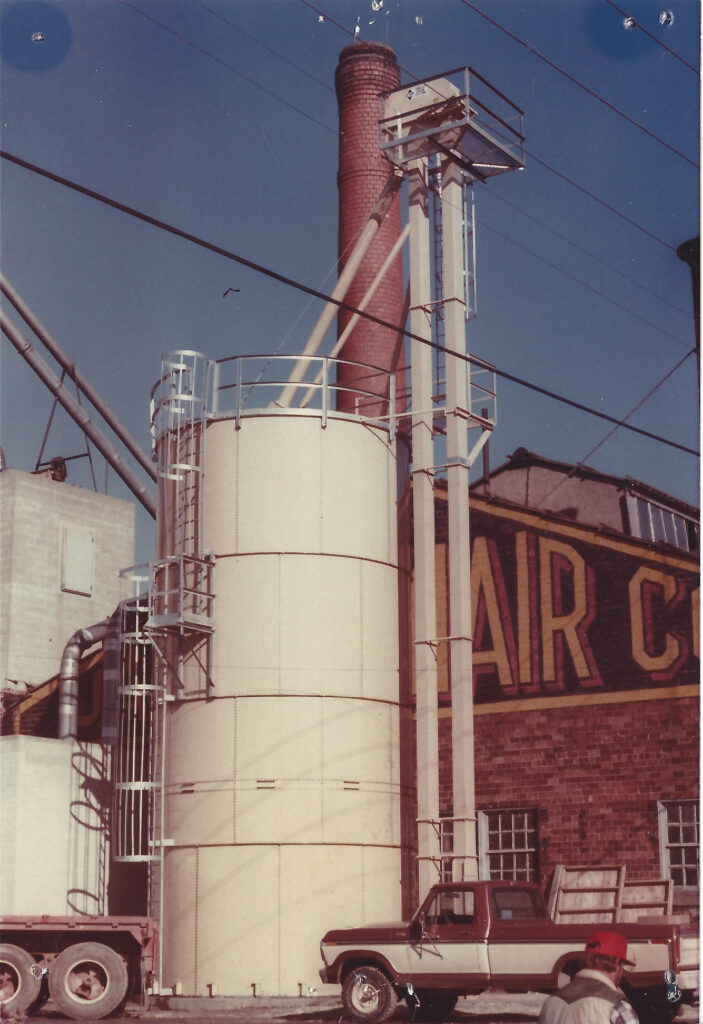

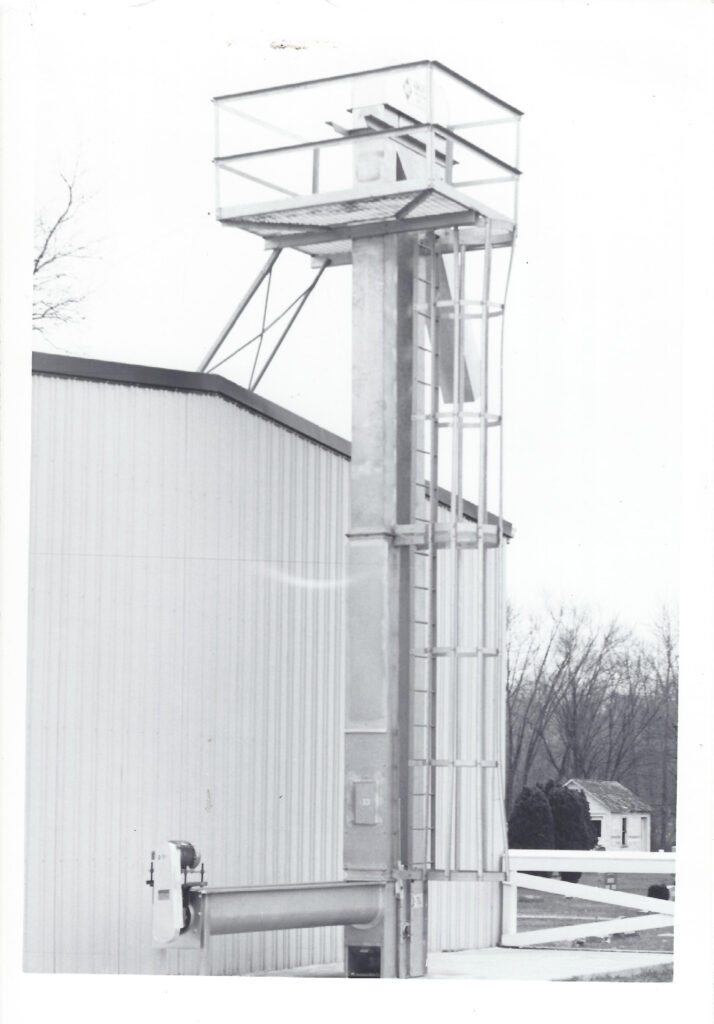

In the early 1960’s, Creighton Brothers in Atwood, Indiana took out bids for a major mill expansion. Paul made his presentation to John Frederich, not having a mobile welder to perform the work. However, when Pauls competitor made their presentation to Mr. Frederich, they, according to Paul, “called me everything but a milk cow, even though they had never met me.” Mr. Frederich was to have said “No one could possibly be that bad”, hired Paul and purchased a welder for him to do the job, taking the cost off the bill. Because of this opportunity, Hensley became a household name in northern Indiana, building bucket elevator legs and industrial grain systems for some of the largest grain elevators and feed mills in the region. In the 1970’s, Hensley employed around fifty people with 10 to 12 service crews on the road full-time, with the new Hensley equipment being delivered to the job site by Paul’s pride and joy; his 1967 Diamond T. After 26 years in the business and many expansions later, Paul and his son Gregg decided to purchase the manufacturing rights and blueprints from I&M Manufacturing and started building bulk feed bodies and bulk ANFO bodies in fall of 1988. In 1990 they produced their first all aluminum feed body, and in 1991, the first all aluminum trailer rolled out the door. Within the first couple years, Hensley focused on the long, multi-axle “Michigan Style” trailers; trailers that had anywhere from 4 to 8 axles and the capability of hauling 40-50 tons.

The first units were designed with chalk and cardboard mock-ups on the floor, but now, state-of-the-art Auto-CAD and SolidWorks 3D engineering programs are used to design the trailers. A large portion of Hensley’s new designs are developed using customer input. At Hensley, focus and attention is paid to every small detail, even down to what others consider insignificant. In 2007, Hensley changed the industry forever with the introduction of the very first Super Auger Trailer. The advent of the 12-15-12 Auger system took the industry to places never before thought to exist. The Hensley Super Auger System, the standard by which all of the other manufacturers are compared, was the first of its kind and has allowed some large livestock producers to double their loads per day, which results in Hundreds of thousands of dollars per year for these operations. Hensley’s customer base now includes some of the largest chicken, egg layer, turkey and hog producers in the United States and around the globe. In December 2012, Robert Janes representing Tyson Foods in Springdale, Arkansas, called inquiring if Hensley would built a custom low center of gravity trailer for them to prevent or reduce roll-over accidents. In January of 2013, Hensley began designing this new trailer and filed for Provisional Patent Status on the first Low Center of Gravity (LCG) Bulk Feed trailer in the industry. This trailer revolutionized the industry, lowering the center of gravity by 25″ over a conventional style trailer. Hensley received their US Patent in 2015 for the trailer, Patent number 9,211,830, the first feed trailer in our industry to achieve such a feat. Since that time, the Generation X LCG trailers make up over 50% of our production.

Another major product line at Hensley that is growing rapidly in is ANFO/Emulsion bodies & trailers. These types of bodies and trailers haul Ammonium Nitrate, Emulsion and Diesel Fuel Oil, and blend these together before being pumped into blast holes. Some of the largest coal and copper mines in the United States are running Hensley ANFO equipment. In 2011 and renewed in 2021, Hensley was approved to build DOT 412 Tanks, allowing the transport of hazardous materials on Federal, State and local highways. Prior to receiving this status, the ANFO bodies were built for Off-Road, Mine use only.

Now over 35 years after Hensley began building transport equipment for the Feed, Grain, Blasting and Wood Pellet industry, Hensley equipment can now be found across the continental United States, Alaska, Hawaii, Canada, Mexico, Central and South America, the middle East and Australia. Hensley has grown from a small, niche manufacturer to one of the largest in the industry.

In the words of Paul Hensley, our Founder and CEO, “We (He and Joyce) can hardly believe that it’s grown this much. I never went into business to become rich or to put anyone else out of business. I just needed a job.” The company that once started with two employees and a small shop now employs over 50 with over 70,000 sq. ft. of manufacturing space. Paul passed in 2013 from brain cancer and Joyce passed on Mother’s Day in 2023. However, the godly values and legacy of integrity they left behind has been instilled in every facet of our company, including 3 more generations of Hensley’s, carrying the torch into the future.

Hensley. We didn’t invent the Feed Trailer…We just made it Better.